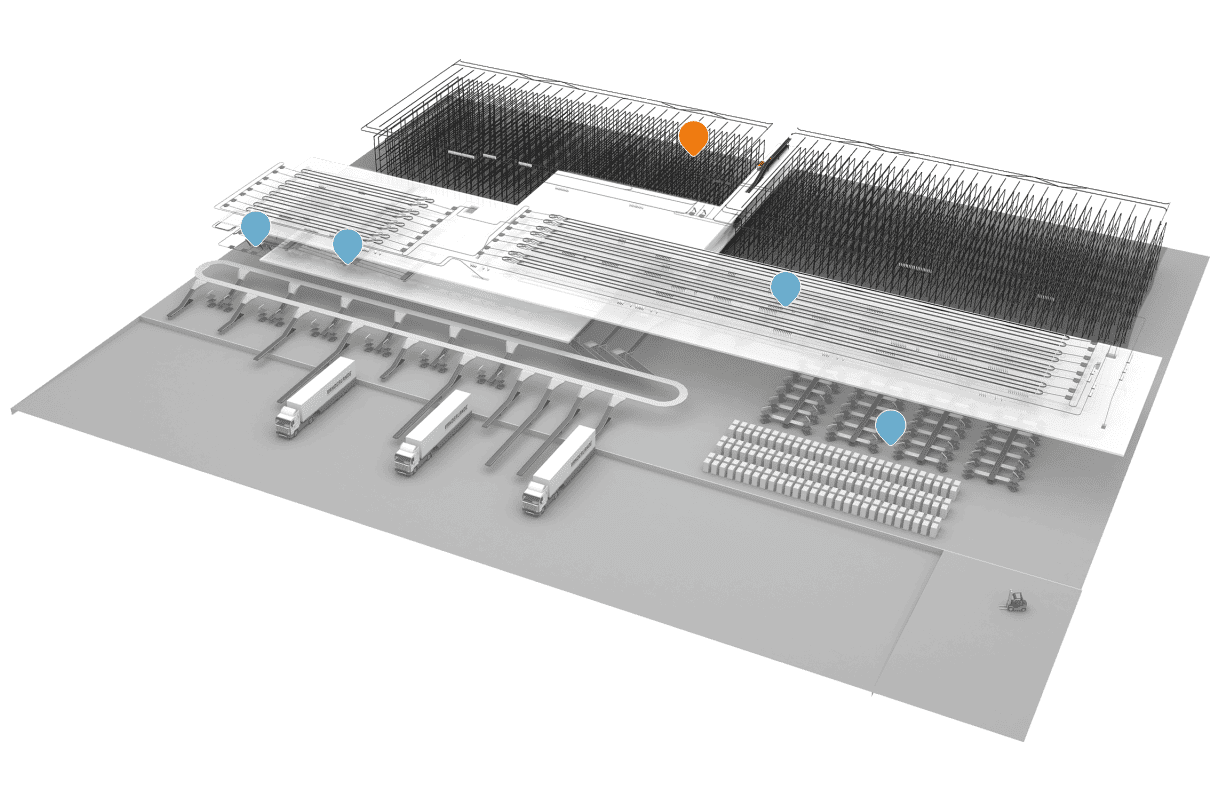

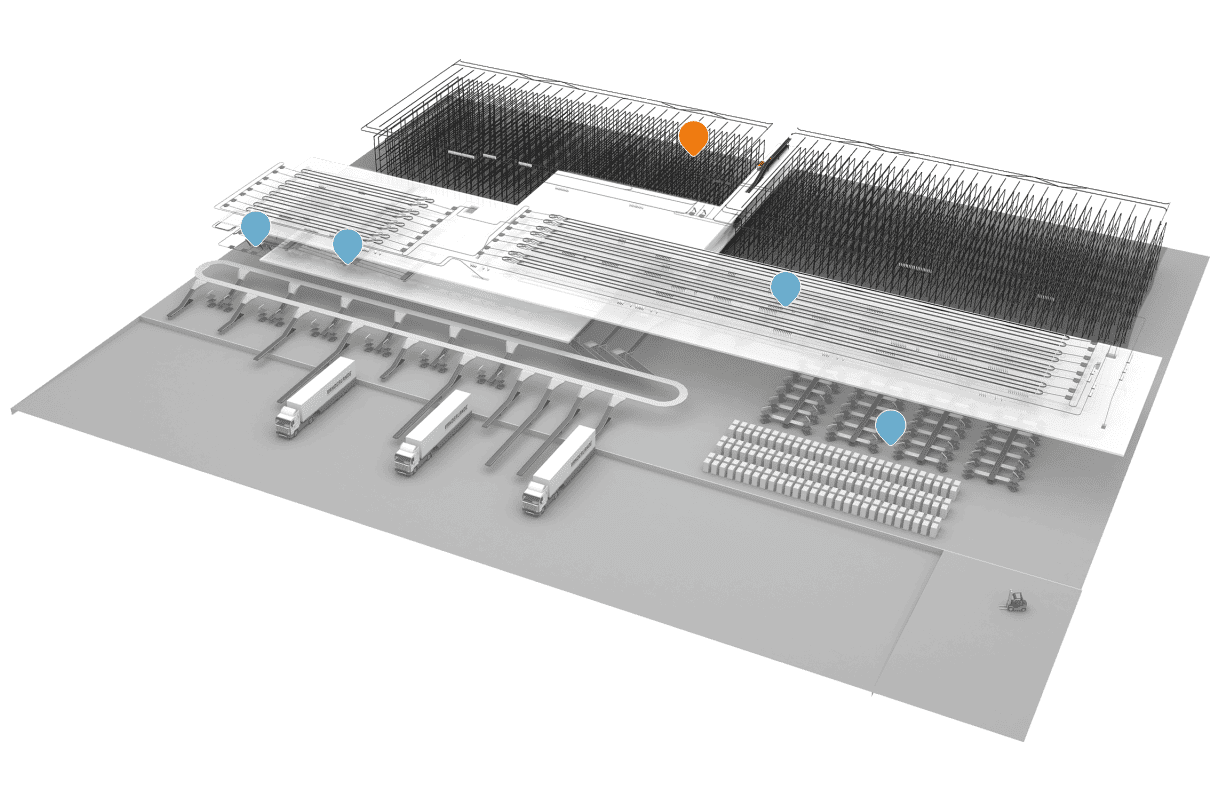

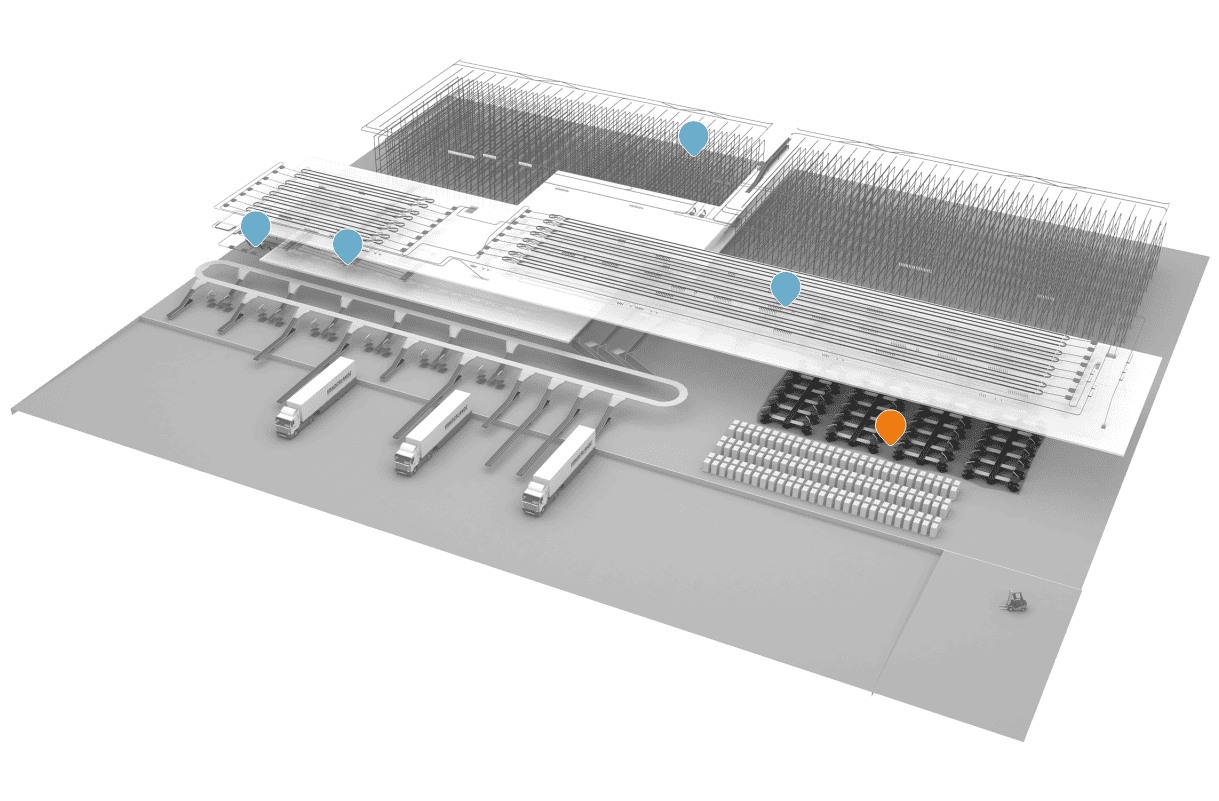

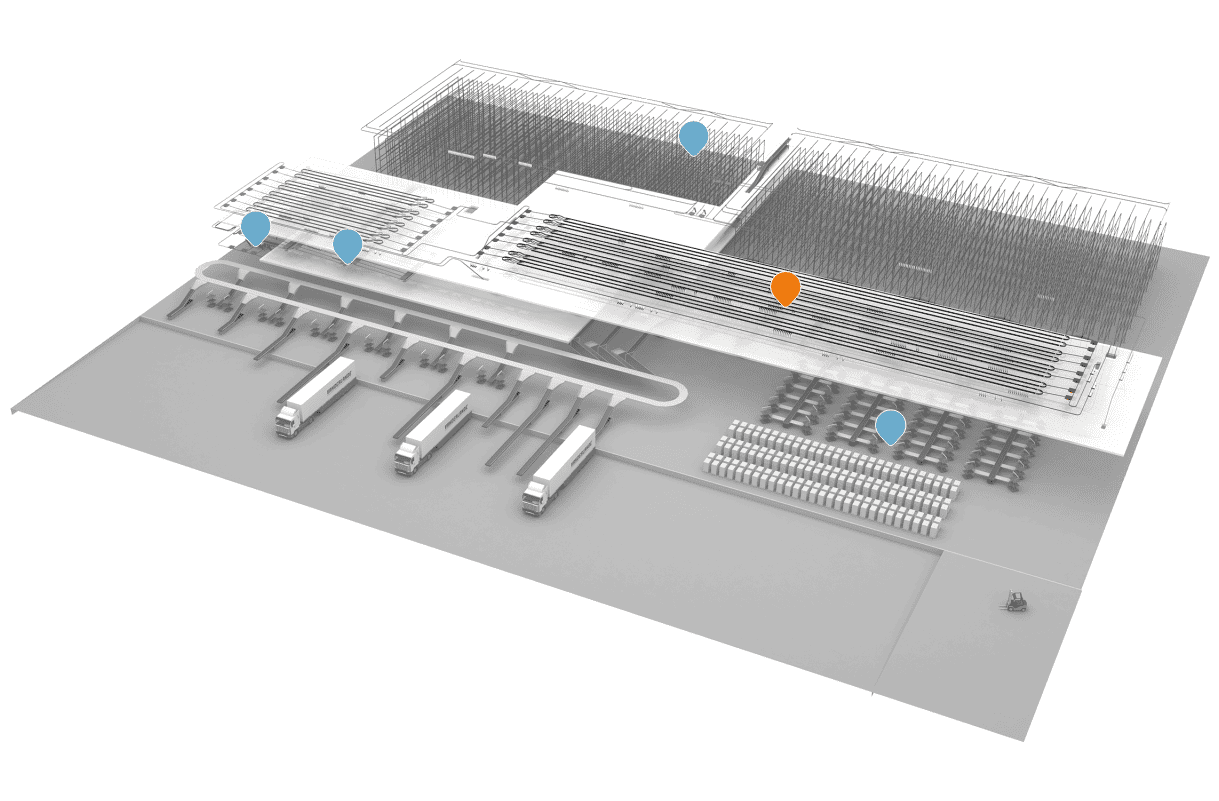

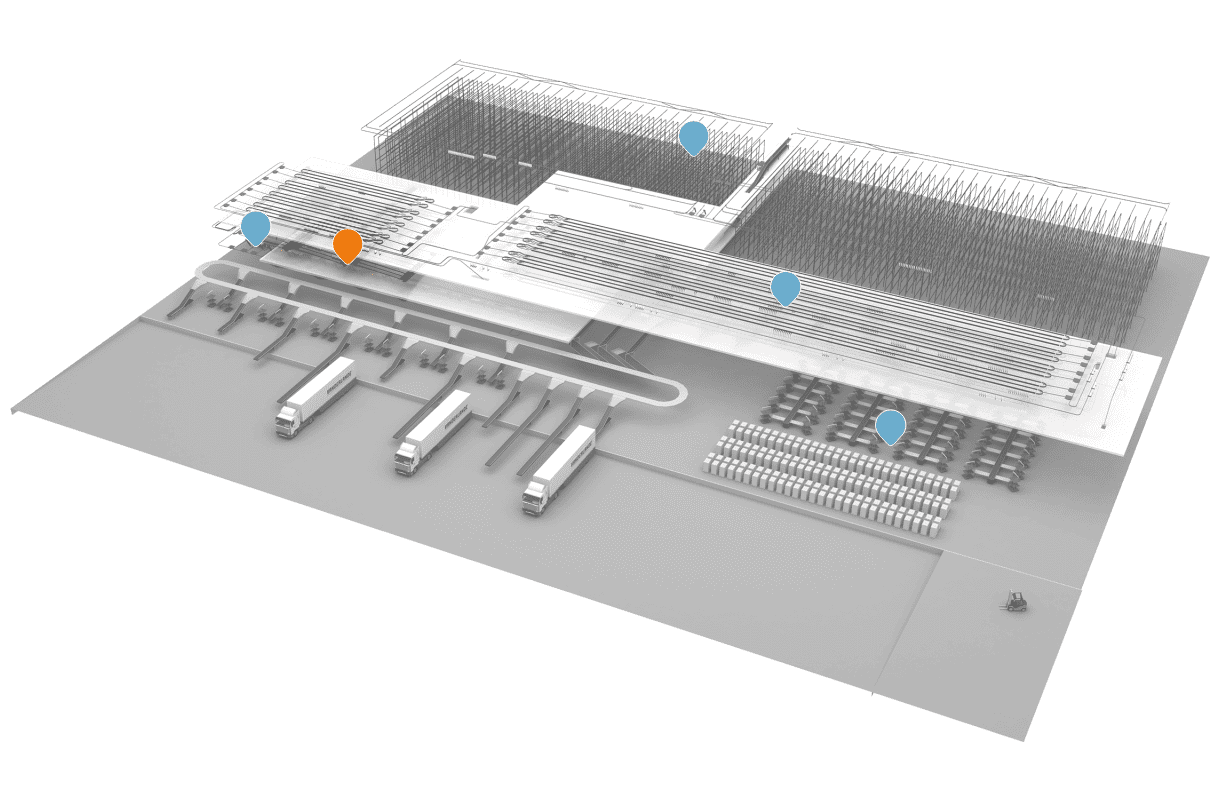

Every company and every market is different. This is reflected in the layout of your warehouse – and the advice offered by our experts.

Picking

Items are picked manually from various warehouse areas in a continuous flow.

Home » Warehousing » Solutions » AIRPICK

Unpredictable demand, seasonal trends and special sale days – there’s always something putting the pressure on your warehouse systems. Then there’s the requirement to increase the variety and volume of products you can handle, and – like your competitors – you have to deal with returns quickly and efficiently.

So how do you meet the high levels of service demanded by your customers? What’s the best way to fulfil thousands of orders? And how do you cope with the need for rapid deliveries?

Our answer to all these questions is efficient picking with automated sortation through AIRPICK – one of our next generation of scalable solutions. AIRPICK tackles today’s challenges with tomorrow’s technology, to offer:

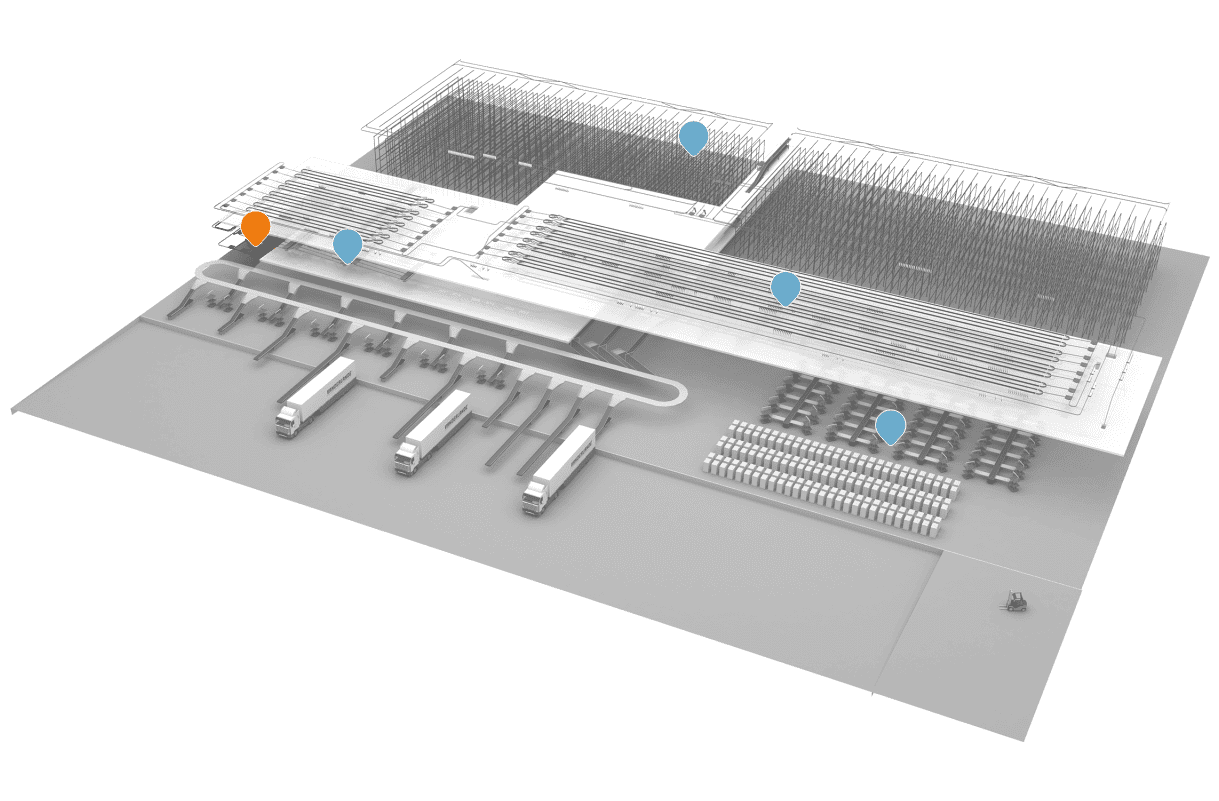

Items are picked manually from various warehouse areas in a continuous flow.

Each pocket is randomly inducted with one item. This can also be done with a smart item robot (optional).

Items are sent into and retrieved from dynamic buffer loops. This also allows for fully automated handling of returned items.

Items are automatically sorted to individual orders and moved in the desired sequence.

Items are presented to the pack operator per order and, if required, in the desired sequence.

AIRTRAX is our innovative and reliable family of products for transporting, sorting, sequencing and storing hanging goods.

Continue readingVISION is our next generation of software that intelligently connects and orchestrates your system’s equipment, robotics, people and processes. It’s our single platform for all automated and manual warehouse functions.

Continue readingEvery company and every market is different. This is reflected in the layout of your warehouse – and the advice offered by our experts.